Hello! It's the first Friday of this month, which means we have a new challenge at Creative Artiste Mixed Media. As always, the theme for the challenge is Anything Mixed Media Goes, with 3 or more mediums being used. For my inspiration project, I made an art journal spread - I started my creative session… Continue reading Watch With Glittering Eyes

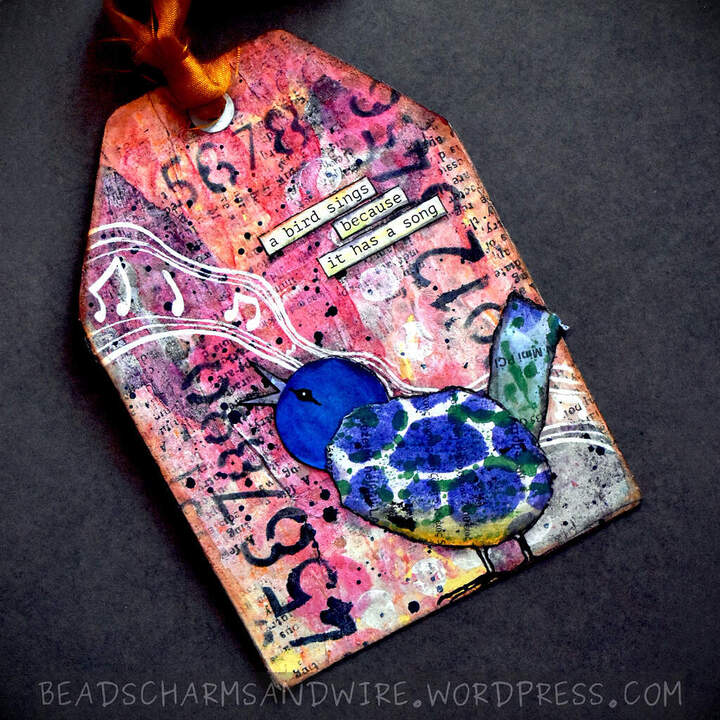

A Bird Sings…

Hello! Today, I'm excited to be featured as a guest designer on the Try it on Tuesday challenge! They always have fun themes, and for the next two weeks, the theme for their challenge is 'Inspired by a Song'. With the weather warming up and the trees blossoming, birds have been more active near our… Continue reading A Bird Sings…

You Define Your Own Life

Hello! It's the first Friday of this month, and we have a new monthly challenge at Creative Artiste Mixed Media. As always, the theme for the challenge is Anything Mixed Media Goes, with 3 or more mediums being used. Here's my inspiration project, a spread that I made recently in my 10x10cm (4x4") art journal… Continue reading You Define Your Own Life

Happy Birthday Tag Duo

Hello! It's one of those times when I forget to talk about a project, and when I realize it, it's already been ages since I made it. 😉 I think it mostly happens with occasion-related projects, like for birthdays. I wouldn't publish the project soon after I made it because I wouldn't want to spoil… Continue reading Happy Birthday Tag Duo

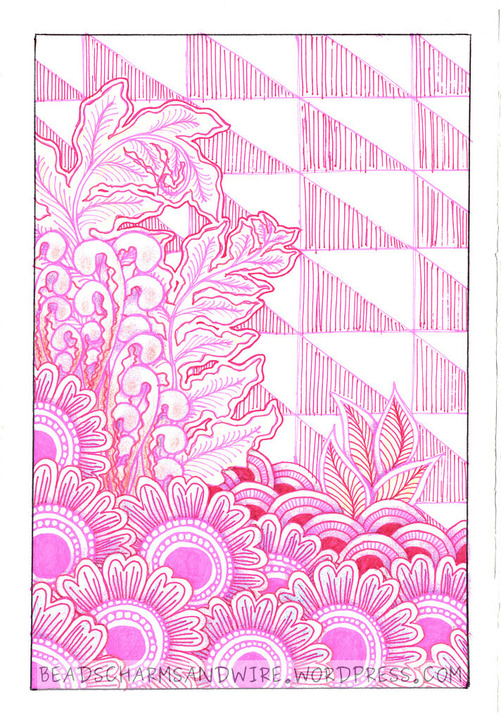

A Dash of Doodles – 7

Hello! Here's a set of large, Zentangle-inspired doodles that I made recently - I used gel pens for these as usual, and oil-pencils for shading. I've lately been picking pens that are not writing so well, so I get the most out of them before they dry up. The pinkish doodles are actually in hot… Continue reading A Dash of Doodles – 7

Spring Begins

Hello! A new month begins today, and since it's also the first Friday of this month, it's time for a new challenge at Creative Artiste. As always, the theme for the challenge is Anything Mixed Media Goes, with 3 or more mediums being used. For my inspiration project, I made a mixed media assemblage tag.… Continue reading Spring Begins

Love Tag

Hello! Here's a recent tag of mine -- I used a curvy, doodle-bordered backing paperboard from a Dylusions-Ranger product--I'm not sure which, it's been a while since I've held on to this paperboard. 🙂 I fussy cut along the doodled border, retaining the doodles at some places and cutting them out at others. On this,… Continue reading Love Tag

Wildflowers

Hello! It's the first Friday of this month, and Creative Artiste is back after an end-of-year break with a brand new monthly challenge! As always, the theme for the challenge is Anything Mixed Media Goes. (Do visit the challenge blog to check out what is accepted by our challenge as mixed media.) I made this… Continue reading Wildflowers

Every Small Thing…

Here's a recent art journal spread of mine. I made this on my 10x10cm (4x4") handmade art journal, which I've been using since early last year. Working on this art journal is so different compared to my A6 one--for one, I can use small images as focals, which I find hard to incorporate into taller… Continue reading Every Small Thing…

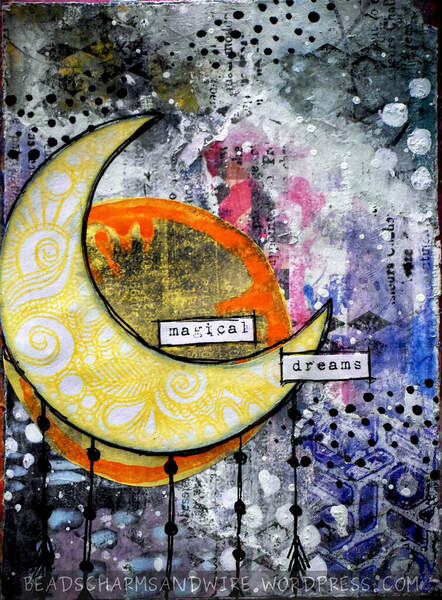

Magical Dreams

Here's a recent art journal page of mine - I made this page using some new supplies that I bought recently--a new stamp, and a much-awaited archival-quality black ink. The page started out with some spray smooshes from a previous session. On this, I used acrylic paints for some finger-painting. I then used more acrylics… Continue reading Magical Dreams